Copyright © KELCO Industries. All Rights Reserved | Sitemap

We co-design application-specific electromechanical solutions from requirements to production with DFM/DFX to reduce risk and lead time for mission-critical systems.

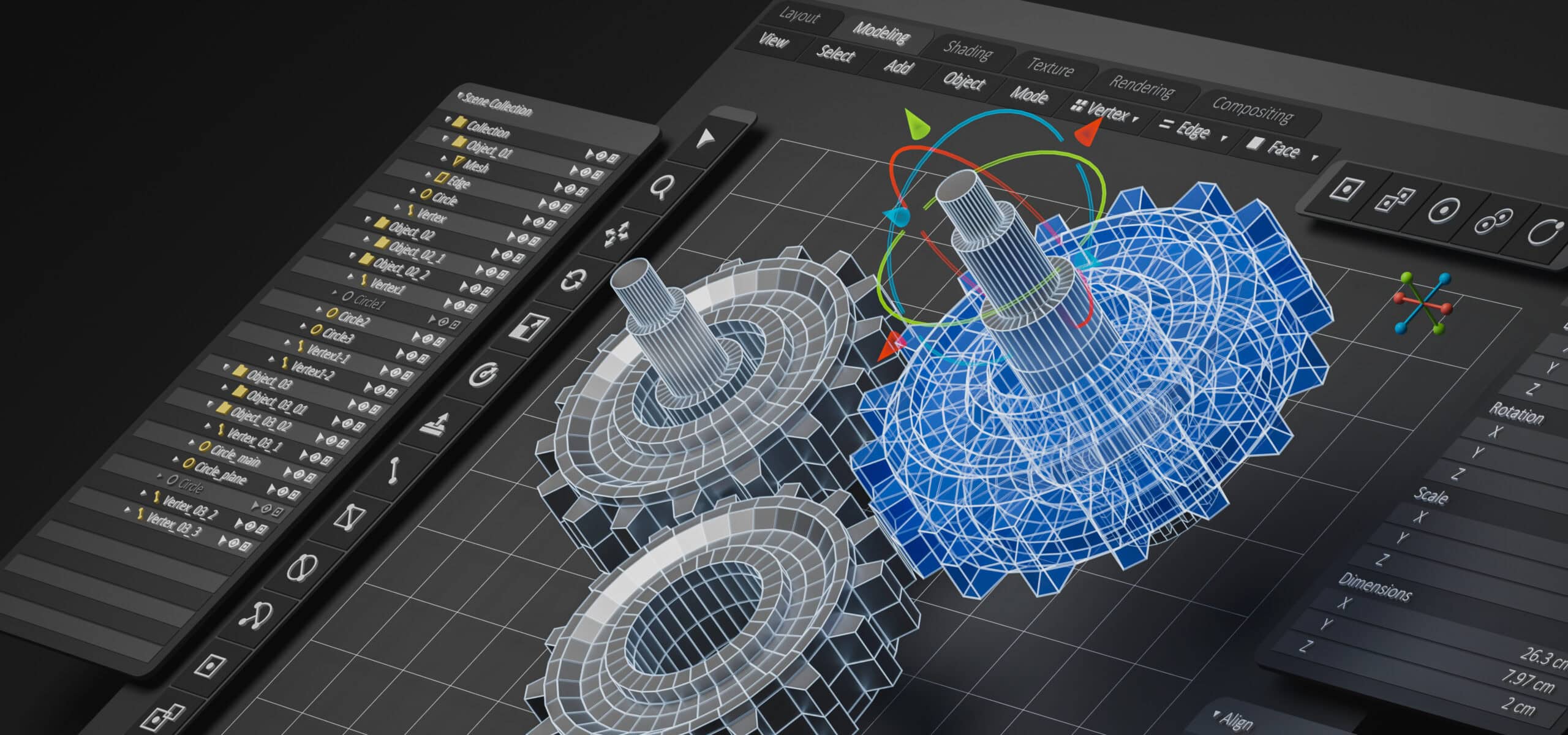

Quick-turn CAD iterations, additive prototypes, and pilot builds to validate form/fit/function fast and accelerate design reviews and qualification.

Electrical, mechanical, and environmental testing (endurance, vibration, temperature, EMI) to prove reliability for aerospace, defense, and demanding industrial use.

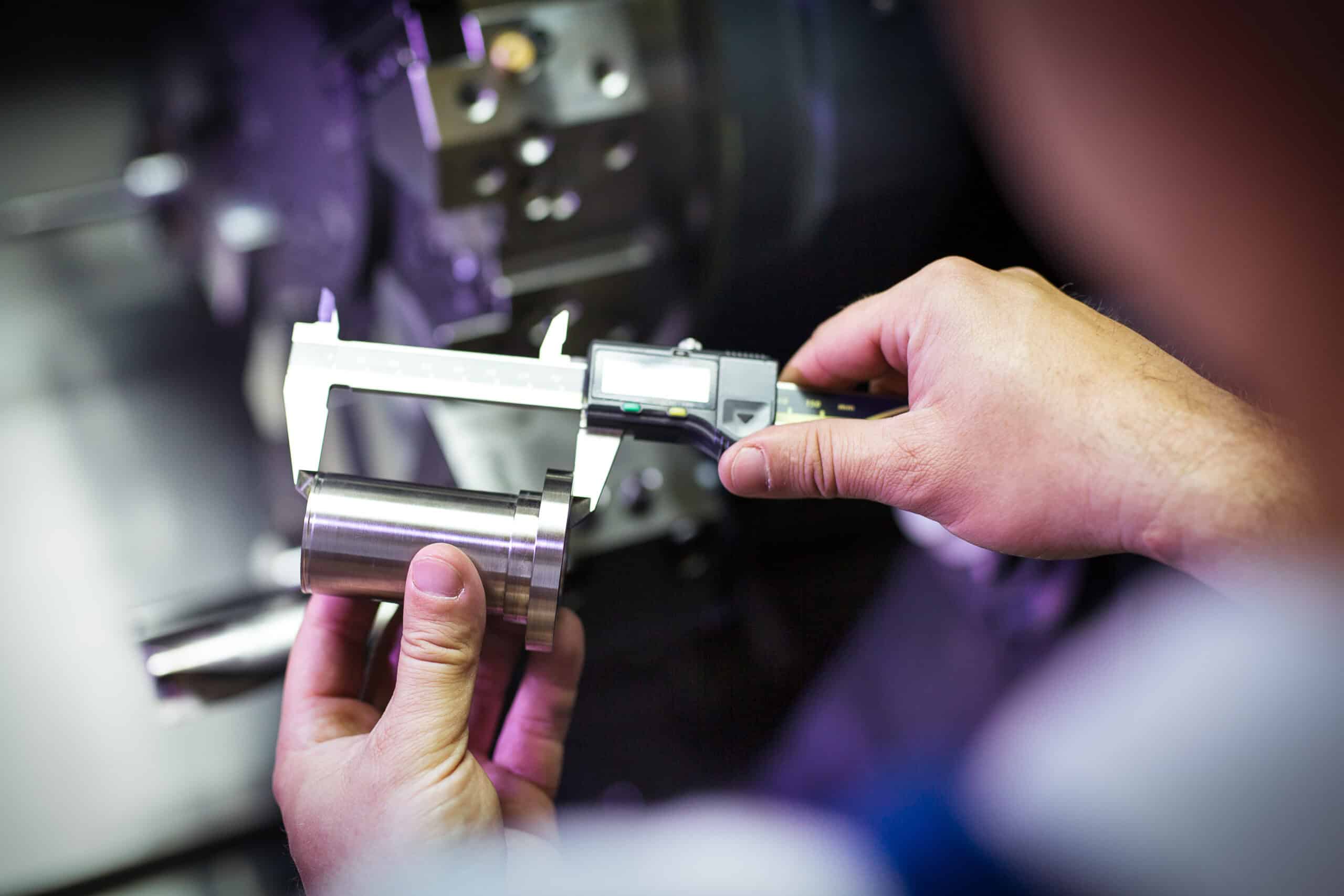

Made in America production with controlled processes, tight tolerances, and final test—supporting both low-volume custom builds and scalable production.

Rigorous quality assurance, material and process traceability, and documentation that support safety-critical programs and long service life.

Sustaining engineering, obsolescence planning, and spare/repair support to keep your platforms supplied and performing for years.

Complete CAD/drawings, BOMs, and change control with support for FAI/PPAP, RoHS/REACH material declarations, and export-controlled projects—simplifying qualification for aerospace, defense, and other regulated industries.

Dedicated program ownership, forecast-driven planning, safety stock/VMI, and scheduled releases to keep mission-critical electromechanical assemblies on time and on budget.

Have Questions?

Connect With an Expert

Copyright © KELCO Industries. All Rights Reserved | Sitemap