Explosion Proof Solenoids

From automotive to aerospace, our solenoids power critical applications across industries worldwide. Experience the difference precision engineering makes.

Explosion-Proof Solenoids — Rugged, Fully Encased, Hazard-Certified

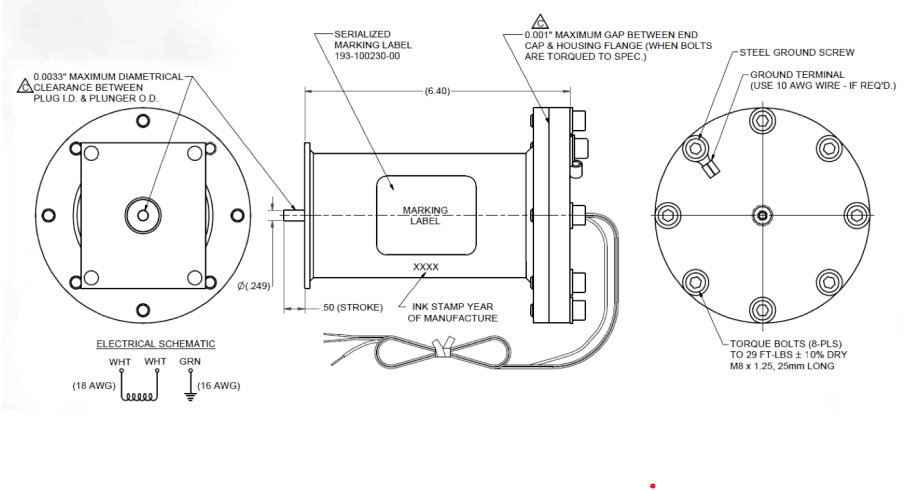

Guardian’s explosion-proof solenoids are engineered for maximum safety and reliability in hazardous environments. Each unit is fully encapsulated to prevent ignition and protect internal components from dust, moisture, and impact. Designed to meet UL Class I, Div I, Groups A–D, ATEX, CSA, and IECEx requirements, these solenoids deliver 30 lbs of force at zero stroke and a 54 lb holding force for continuous-duty performance. Ideal for industrial, aerospace, and energy applications requiring certified ignition protection and dependable operation under extreme conditions. Proudly made in the USA.

Specifications

– 30 pounds at 0 inch stroke

– Holding force 54 pounds

– 0.5 inch stroke

– Continuous duty

– Coil Resistance 170 Ω (±10% @20°C)

– 125 VDC, 0.8 A, 100 W

– Dielectric strength 1500 V 60 Hz min.

– Drop-out voltage 18 VDC min. (25 lb. spring force)

– Pick-up voltage 85 VDC max. (no load)

– Ambient temp -20 – 82°C

Need a non‑standard stroke, force curve or package?

If you’re designing the next generation of aerospace systems — whether it’s a fixed-wing UAV, a supersonic commercial jet, or a cutting-edge defense platform — we’re your partner for mission-critical control solutions.

Frequently Asked Questions