Expansion Loops

Keflex™ Expansion Loops are engineered to absorb thermal expansion, lateral offset, and unpredictable seismic movement in industrial, mechanical, and building piping systems. Designed for high-pressure, ultra-clean, and corrosive applications, each loop protects equipment and piping from stress, fatigue, and distortion.

Unlike bulky bellows-type expansion joints, the in-the-wall design offers a compact footprint, easier installation, and reduced anchor and guide requirements. Ideal for HVAC, industrial, and energy systems, Keflex™ Expansion Loops provide a clean, space-saving, long-life solution for managing thermal growth and movement in any direction.

Features & Benefits

– Motion in Three Planes – Accommodates offset, lateral, and axial movement within piping systems.

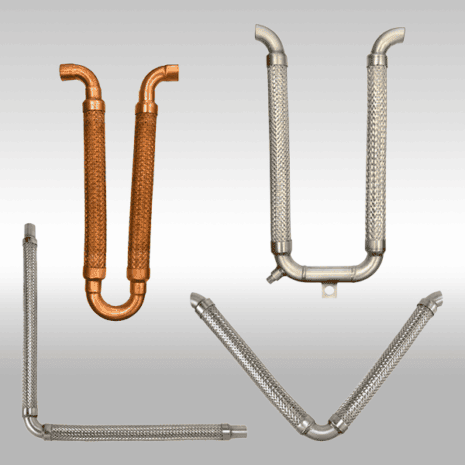

– “L”, “U”, or “V” Configurations – Available in multiple designs to meet specific layout and space requirements.

– Variety of Sizes & End Fittings – Offered with multiple diameter and end connection options for easy integration.

– Nested Configurations – Compact, space-saving design simplifies installation in tight mechanical rooms.

– Maximum Vibration Absorption – Reduces mechanical stress, noise, and fatigue across piping systems.

– Simplifies Multi-Pipe Protection – Provides an efficient solution for protecting adjacent runs from thermal or seismic movement.

– Seismic Protection – Maintains connectivity and flow even during catastrophic or high-vibration events.

Applications

– Thermal expansion compensation in all types of piping systems

– Seismic protection of equipment and piping

– High-vibration process or mechanical systems

– Offset and misaligned piping layouts

– Installations with limited space or multiple pipe runs

Markets Served

– Commercial and industrial construction

– HVAC and mechanical systems

– Power generation and utilities

– Chemical and process industries

– Water and wastewater treatment

– Seismic and high-vibration infrastructure

Expansion Loops (downloadable PDFs)

Need a custom flexible metal solution?

If your system requires non-standard movement, pressure, or connection configurations, Flex-Weld engineers can design and fabricate custom expansion joints, metal bellows, and flexible hose assemblies to your exact specifications. We’ll tailor materials, end fittings, ply count, and cycle life to meet your application—whether it’s HVAC, power generation, chemical processing, or aerospace.