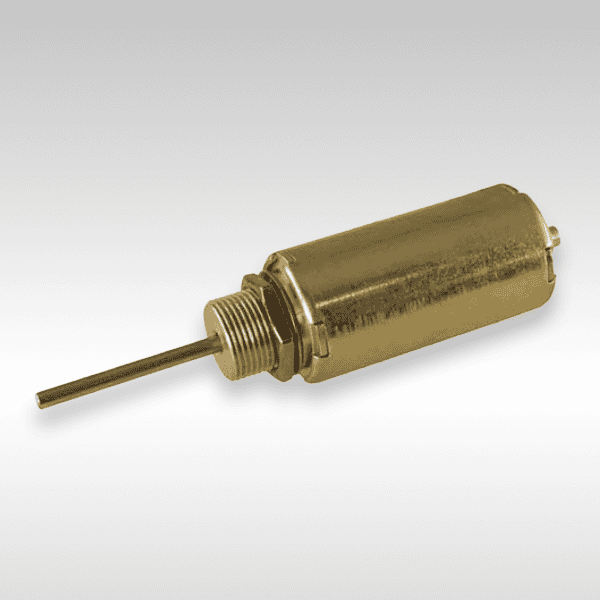

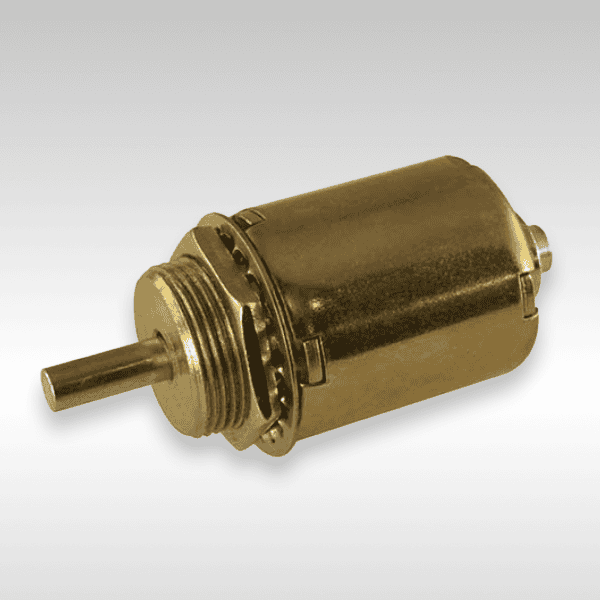

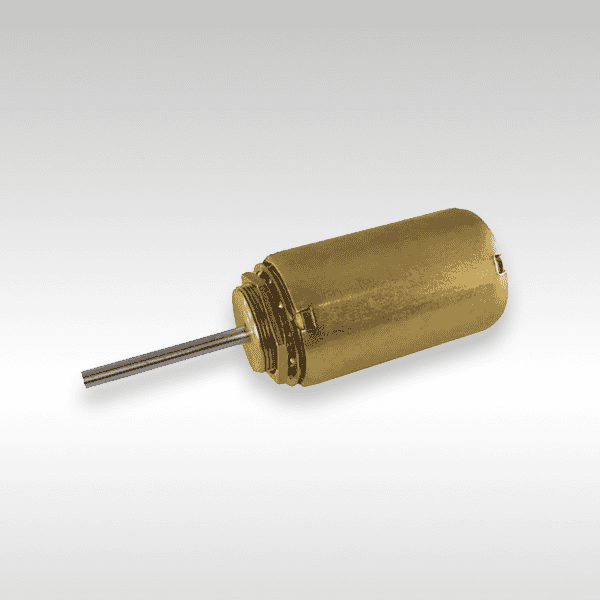

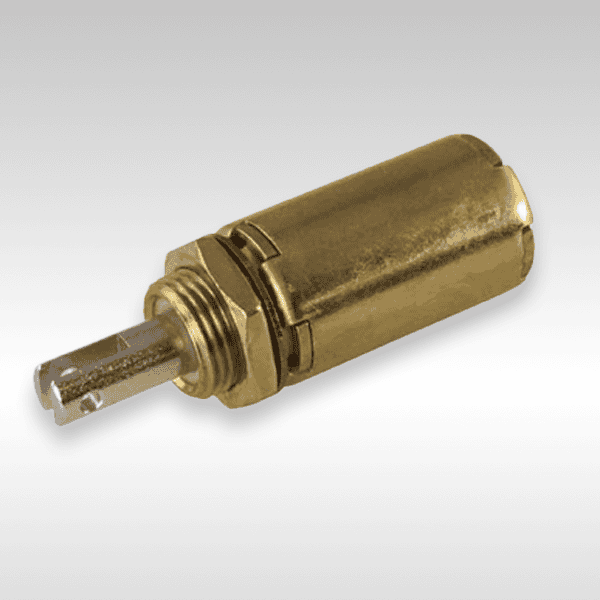

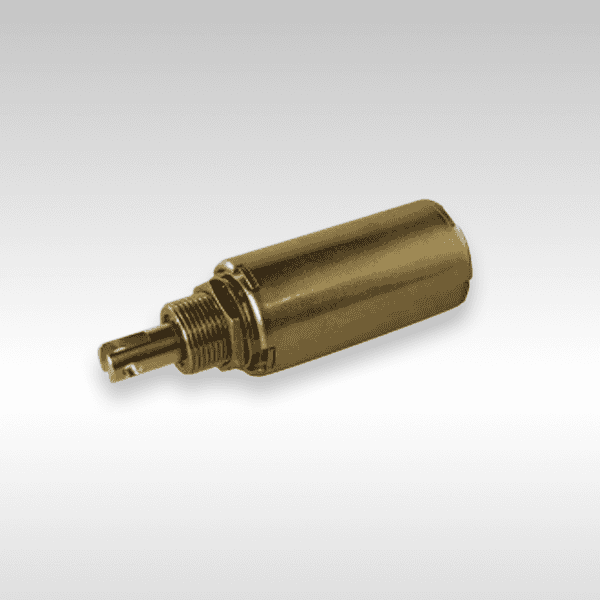

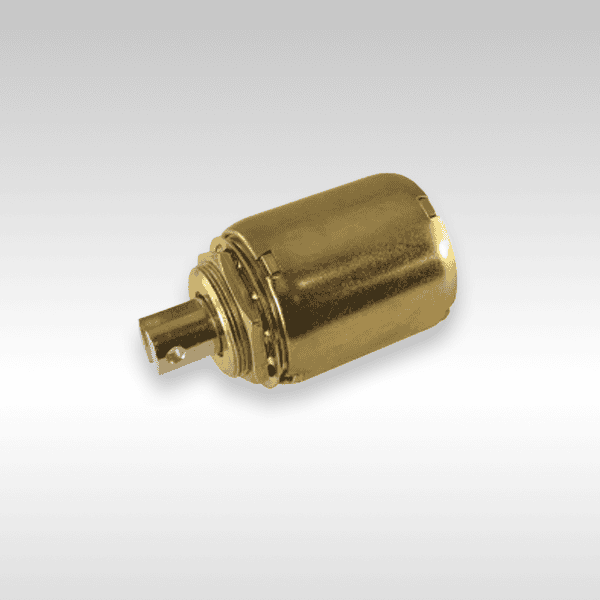

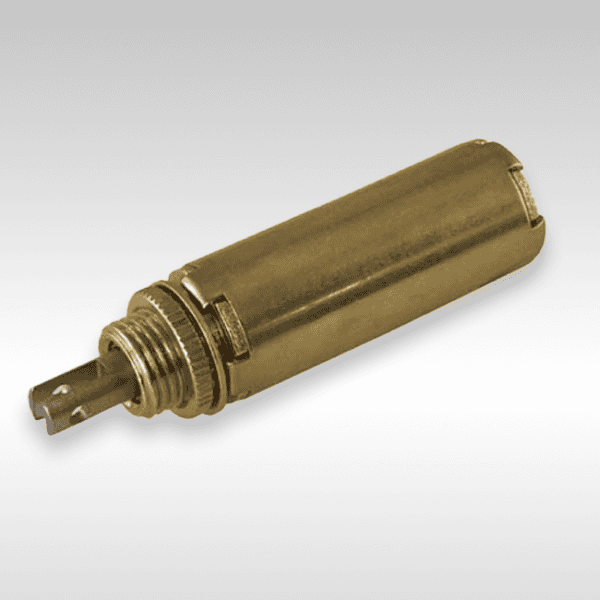

Tubular Solenoids

From automotive to aerospace, our solenoids power critical applications across industries worldwide. Experience the difference precision engineering makes.

Tubular DC Solenoids for Aerospace, Defense & Industrial Actuation

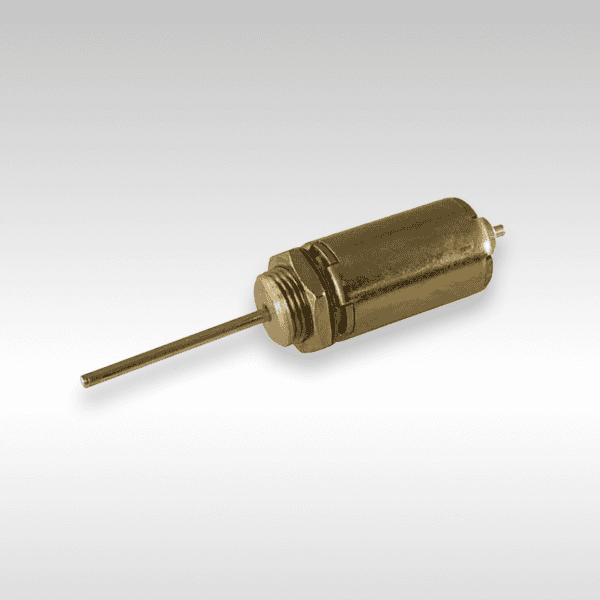

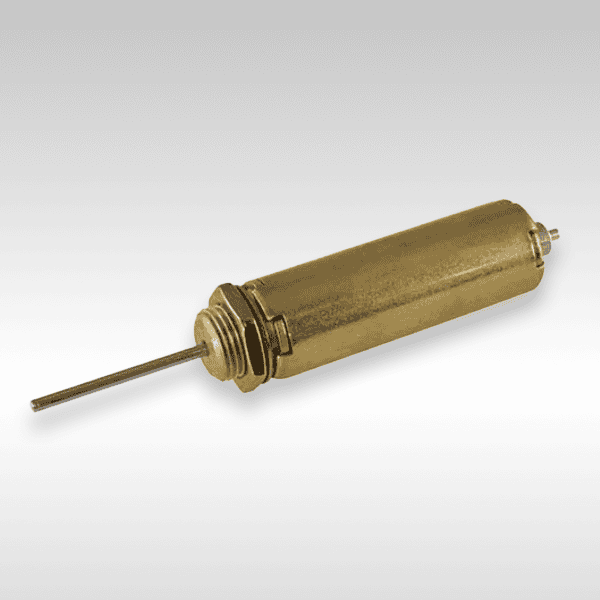

Discover U.S.‑built tubular push‑ and pull‑type solenoids trusted by aerospace OEMs, defense prime contractors and high‑reliability industrial systems. Guardian’s catalog spans 0.25–1.0 in strokes and up to 40 oz [11 N] force, with high‑temperature windings, extended‑life bushings and hermetic sealing options. Proven in fuel‑control valves, landing‑gear locks, door latches and missile‑release mechanisms, these solenoids meet AS9100, MIL‑DTL and UL requirements while offering custom coil, plunger and mounting configurations for rapid integration into mission‑critical platforms.

Sort by Push or Pull

| Image | Part # | Dia (in/mm) | Length (in/mm) | Max Stroke (in/mm) | Cont. Duty (oz/N) | Int. Duty (oz/N) | Datasheet | Request quote | hf:tax:pa_solenoid-type |

|---|---|---|---|---|---|---|---|---|---|

| TP3.5x9 | 0.438 / 11.1 | 1.18 / 30 | 0.25 / 6.4 | 1 / 0.3 | 2 / 0.6 | | push | ||

| TP4x7 | 0.5 / 12.7 | 0.89 / 22.6 | 0.25 / 6.4 | 1 / 0.3 | 2 / 0.6 | | push | ||

| TP4x12 | 0.5 / 12.7 | 1.51 / 38.4 | 0.25 / 6.4 | 2 / 0.6 | 3 / 0.8 | | push | ||

| TP4x16 | 0.5 / 12.7 | 2.01 / 51.1 | 0.25 / 6.4 | 2.5 / 0.7 | 3 / 0.8 | | push | ||

| TP6x12 | 0.75 / 19.1 | 1.54 / 39.1 | 0.375 / 9.5 | 5 / 1.4 | 9 / 2.5 | | push | ||

| TP8x9 | 1 / 25.4 | 1.17 / 29.7 | 0.5 / 12.7 | 3 / 0.8 | 15 / 4.2 | | push | ||

| TP8x16 | 1 / 25.4 | 2.04 / 51.8 | 0.75 / 19.1 | 4 / 1.1 | 14 / 3.9 | | push | ||

| TP12x13 | 1.5 / 38.1 | 1.68 / 42.7 | 0.75 / 19.1 | 15 / 4.8 | 28 / 7.8 | | push | ||

| TP12x19 | 1.5 / 38.1 | 2.43 / 61.7 | 1 / 25.4 | 14 / 3.2 | 32 / 8.9 | | push | ||

| T12x19 | 1.5 / 38.1 | 2.43 / 61.7 | 1 / 25.4 | 18 / 5 | 40 / 11.1 | | pull | ||

| T4x7 | 0.5 / 12.7 | 0.89 / 22.6 | 0.25 / 6.4 | 1 / 0.3 | 2 / 0.6 | | pull | ||

| T4x12 | 0.5 / 12.7 | 1.51 / 38.4 | 0.25 / 6.4 | 2 / 0.6 | 3 / 0.8 | | pull | ||

| T4x16 | 0.5 / 12.7 | 2.01 / 51.1 | 0.25 / 6.4 | 3 / 0.8 | 4 / 1.1 | | pull | ||

| T6x12 | 0.75 / 19.1 | 1.54 / 39.1 | 0.375 / 9.5 | 5 / 1.4 | 9 / 2.5 | | pull | ||

| T8x9 | 1 / 25.4 | 1.17 / 29.7 | 0.5 / 12.7 | 4 / 1.1 | 15 / 4.2 | | pull | ||

| T12x13 | 1 / 25.4 | 1.68 / 42.7 | 0.75 / 19.1 | 10 / 2.8 | 30 / 8.3 | | pull | ||

| T3.5x9 | 0.438 / 11.1 | 1.18 / 30 | 0.25 / 6.4 | 1 / 0.3 | 2 / 0.6 | | pull |

Need a non‑standard stroke, force curve or package?

If you’re designing the next generation of aerospace systems — whether it’s a fixed-wing UAV, a supersonic commercial jet, or a cutting-edge defense platform — we’re your partner for mission-critical control solutions.

Frequently Asked Questions