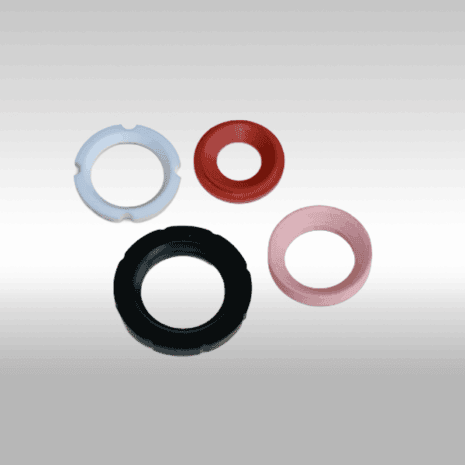

Ball Valve Seals

WCT Ball Valve Seals are engineered for precise, reliable performance across fluid-handling industries. Manufactured from advanced PTFE and 316L stainless steel, they ensure leak-free sealing, chemical resistance, and long service life. Available as ball valve seats, stem packings, cavity fillers, and butterfly valve seats, each component is precision-machined to maintain tight tolerances and superior durability. Designed for enhanced system integrity and reduced maintenance, WCT ball valve seals provide dependable performance under pressure—keeping your process lines running efficiently and safely.

Key Benefits

Enhanced System Reliability

Maintains seal integrity for consistent fluid performance

Long Service Life

Resists wear, pressure, and chemical degradation

Precision Fluid Control

Ensures tight sealing for smooth, leak-free operation

Cost-Effective Durability

Delivers long-term value with minimal maintenance requirements

Enhanced System Reliability

Maintains seal integrity for consistent fluid performance

Long Service Life

Resists wear, pressure, and chemical degradation

Precision Fluid Control

Ensures tight sealing for smooth, leak-free operation

Cost-Effective Durability

Delivers long-term value with minimal maintenance requirements

Industries We Serve

Food & Beverage

Brewery

Dairy

Biotech

Cosmetic and Personal Care

Water Treatment & Purification

Cannabis Extraction

Food & Beverage

Brewery

Dairy

Biotech

Cosmetic and Personal Care

Water Treatment & Purification

Cannabis Extraction

Materials and Specifications

Western Consolidated Technologies manufactures Ball Valve Seals from a range of high-performance materials designed to withstand demanding fluid handling environments. Common options include PTFE, filled PTFE, and other engineered polymers selected for their durability, low friction, and chemical compatibility. Each seal is produced to meet precise dimensional standards and can be customized to fit specific valve designs or application requirements.