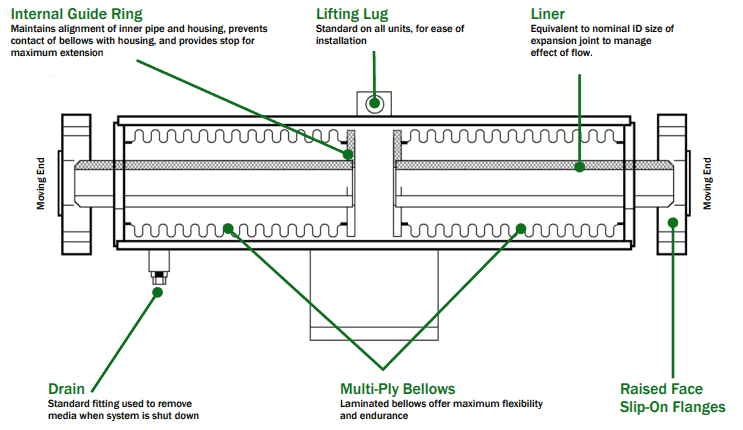

Externally Pressurized Expansion Joints

Flex-Weld Externally Pressurized Expansion Joints combine multi-ply stainless steel construction with a robust pressure-balanced design to ensure long-term reliability in high-pressure and high-temperature piping systems. The multi-ply configuration provides critical redundancy and safety—if one ply fails, remaining plies maintain containment until replacement. Optimized for cycle life and fatigue resistance, these joints deliver lower thrust forces and require less live length, making them ideal for space-limited installations.

By replacing high-maintenance packed joints, pipe loops, and costly equalizing systems, Flex-Weld externally pressurized joints offer a compact, efficient, and low-stress solution that ensures consistent performance and system protection under demanding service conditions.

SINGLE EPEJ FEATURES & BENEFITS

Up to 8″ of axial motion

– Eliminates the need for multiple joints in a long run

150 PSI or 300 PSI designs

– Meets low- or high-pressure applications

Integral Liner

– Manages effect of flow

Custom or standard material selection

– Meets most application needs

Multiple end fitting options

– Weld Ends

– Grooved Ends

– Raised Face Slip on Flanges

DUAL EPEJ FEATURES & BENEFITS

Up to 16″ of axial motion

– Eliminates the need for multiple joints in a long run

150 PSI or 300 PSI designs

– Meets low- or high-pressure applications

Integral Liner

– Manages effect of flow

Custom or Standard Material Selection

– Meets most application needs

Multiple end fitting options

– Weld Ends

– Grooved Ends

– Raised Face Slip on Flanges

CAPABILITIES

– Multi-ply Safety Factors

– Cycle Life Optimization

– Compact Design

– Lower Thrust Forces

– Increased flexibility

– Higher pressures attainable

– Lower spring rates & higher elasticity

– Fail safe design

Externally Pressurized Expansion Joint Submittals (downloadable PDFs)

| Submittals Single Bellows Externally-Pressurized Expansion Joints (4” – 8” Axial Movement) | |||

|---|---|---|---|

| 4 inch | 6 inch | 8 inch | |

| Pipe Weld Ends | |||

| Raised Face Flange Ends | |||

| Grooved Ends | |||

| Submittals Dual Bellows Externally-Pressurized Expansion Joints (8” – 16” Axial Movement) | |||

| 8 inch | 12 inch | 16 inch | |

| Pipe Weld Ends | |||

| Raised Face Flange Ends | |||

| Grooved Ends | |||

Need a custom flexible metal solution?

If your system requires non-standard movement, pressure, or connection configurations, Flex-Weld engineers can design and fabricate custom expansion joints, metal bellows, and flexible hose assemblies to your exact specifications. We’ll tailor materials, end fittings, ply count, and cycle life to meet your application—whether it’s HVAC, power generation, chemical processing, or aerospace.